Jun 25, 2021 Ans: Following steps are involved in the extraction of Aluminium from bauxite-. 1.The concentration of the ore through Bayer’s process (Leaching) In this process, bauxite is treated with to form sodium aluminate, which further reduces with and gives pure alumina. The reaction is as follows-. 2.

Read More

The extraction of aluminium involves two steps that is, purification of bauxite by Baeyer's process and electrolysis of alumina. 1. Purification of bauxite by Baeyer's process In the Baeyer's process, the bauxite ore is heated with concentrated NaOH solution under pressure (Aluminum is purified by leaching method).The alumina dissolves as sodium meta aluminate.

Read More

Jul 20, 2020 A simple but detailed lesson on the extraction of aluminium from bauxite.This video is based on the O'level chemistry syllabus. It covers the uses and proper...

Read More

Apr 11, 2016 Results at this plant are excellent, enabling this plant to realize a high alumina extraction with a minimum soluble loss. Visit a Bauxite Mine Aluminum Facts. Atomic Number (number of protons in the nucleus): 13; Atomic Symbol (on the Periodic Table of Elements):

Read More

Jun 09, 2020 How is aluminium extracted from its ore (bauxite)? What is the Hall-Heroult Process?Watch to find out!Catering for IGCSE and SPM students. Don't forget to li...

Read More

Sep 01, 2012 Extraction process. Bayer-process. Firstly, crushed bauxite is treated with moderately concentrated sodium hydroxide solution. The concentration, temperature and pressure used differs based on the source of the bauxite and the form of aluminium oxide it contains. Temperatures are generally range from 140°C to 240°C; pressures can be up to ...

Read More

Dec 16, 2020 In examining the electrolytic extraction of aluminium from bauxite and alumina, we must first briefly explain the element called aluminium and the minerals and ores that contain this very important metallic element. Aluminum is the third most plentiful element in the earth’s crust, being found abundantly as trioxosilicates(IV) in rocks and clays. . The main source of aluminum is the mineral ...

Read More

Bauxite is the name given to aluminium ore. To generate aluminium oxide, bauxite is purified, a white powder form which aluminium can be extracted. Aluminium oxide has a very high melting point of more than 2000 ° C so melting it would be costly. Aluminium oxide in water does not dissolve, but in molten cryolite, it dissolves.

Read More

Avoiding the environmental problems in the extraction of aluminium from the bauxite. Not having to find space to dump the unwanted aluminium if it wasn't recycled. (Offsetting these to a minor extent) Energy and pollution costs in collecting and transporting the recycled aluminium. Uses of aluminium. Aluminium

Read More

2.1 Extraction of Aluminum The extraction of aluminum from its ore and subsequent processing into finished prod-ucts takes place in a series of successive operations, each largely independent of the other. Generally the various processes are carried out at different plant sites. A summary of production steps from the bauxite

Read More

Nov 09, 2010 What Aluminum Extraction Really Does to the Environment ... the entire process of transforming raw bauxite into aluminum is incredibly energy intensive, requiring copious amounts of electricity, water and resources to produce (that is the main reason why power plants are built solely to support the aluminum

Read More

Bauxite Mining. The aluminium production process can be broken down into three stages; first bauxites, which contain aluminium, are extracted from the ground. Second, bauxites are processed into alumina or aluminium oxide, and finally in stage three, pure aluminium is produced using electrolytic reduction, a process in which aluminium oxide is ...

Read More

Bauxite ore is a mixture of hydrated aluminium oxides and compounds of other elements such as iron. The aluminium compounds in the bauxite may be present as gibbsite 2(Al(OH) 3), böhmite (γ-AlO(OH)) or diaspore (α-AlO(OH)); the different forms of the aluminium component and the impurities dictate the extraction conditions. Aluminum oxides and hydroxides are amphoteric, meaning that they are ...

Read More

bauxite processing plant equipment for philippines. Philippines bauxite mining sector to benefit from Canada's AlCircle. Processing Plant In The PhilippinesProcessing appliions and equipment for food and beverages. Bauxite Wikipedia. Bauxite, an aluminium ore, is the world's main source of aluminium.

Read More

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators ...

Read More

Bauxite is a mixture of aluminium minerals, clay minerals, and ... beneficiation plant that washes the bauxite and sends the high silica fines (kaolinite and/or quartz) to a tailings dam prior to ship ... adding an organic removal facility, e.g. oxalate plant. Metallurgical extraction –The Alumina Refinery. iht otios iht rter

Read More

The amount of bauxite residue produced by an alumina plant or refinery is primarily dependent on the sources of the bauxite and secondarily on the extraction conditions used by the plant. In the extreme, this can vary from 0.3 to as high as 2.5 tonnes of residue per tonne of alumina produced, though typically

Read More

The extraction of aluminium involves two steps that is, purification of bauxite by Baeyer's process and electrolysis of alumina. 1. Purification of bauxite by Baeyer's process In the Baeyer's process, the bauxite ore is heated with concentrated NaOH solution under pressure (Aluminum is purified by leaching method).The alumina dissolves as sodium meta aluminate.

Read More

Sep 01, 2012 Extraction process. Bayer-process. Firstly, crushed bauxite is treated with moderately concentrated sodium hydroxide solution. The concentration, temperature and pressure used differs based on the source of the bauxite and the form of aluminium oxide it contains. Temperatures are generally range from 140°C to 240°C; pressures can be up to ...

Read More

Nov 09, 2010 What Aluminum Extraction Really Does to the Environment ... the entire process of transforming raw bauxite into aluminum is incredibly energy intensive, requiring copious amounts of electricity, water and resources to produce (that is the main reason why power plants are built solely to support the aluminum industry).

Read More

Primary aluminum production begins with the mining of bauxite ore, a hydrated oxide of aluminum consisting of 30 to 56 percent alumina (A l2O3) and lesser amounts of iron, silicon, and titanium. The ore is refined into alumina by the Bayer process. The alumina is then shipped to a primary aluminum plant for electrolytic reduction to aluminum.

Read More

The amount of bauxite residue produced by an alumina plant or refinery is primarily dependent on the sources of the bauxite and secondarily on the extraction conditions used by the plant. In the extreme, this can vary from 0.3 to as high as 2.5 tonnes of residue per tonne of alumina produced, though typically

Read More

Alumina is the common name given to aluminum oxide (Al2O3). Alumina is produced from bauxite, an ore that is mined from topsoil in various tropical and subtropical regions. The Bayer process, discovered in 1887, is the primary process by which alumina is extracted from bauxite.

Read More

May 15, 2020 Contents1 Occurrence and Extraction2 Extraction of Aluminium 2.1 1) Purification of Bauxite2.2 2) Electrolysis of fused Alumina2.3 3) Refining of Aluminium Occurrence and Extraction Aluminium occurs widely as a constituent of rocks and soils. The main ores of aluminium are : Bauxite : Al2O3.2H2O Cryolite : Na3AlF6 Feldspar: KAlSi3O8 Mica : KAlSi2O10(OH)2 In India, aluminium []

Read More

Mar 07, 2020 Bauxite residue is a high volume by-product generated during the extraction of alumina from bauxite ore (Bayer process). The long-term containment of residue is associated with environmental risks due to potential dusting and surface run-off. While rehabilitation of residue is viewed as a suitable approach for minimizing this risk, there is need for completion criteria. In particular,

Read More

Bauxite ore is a mixture of hydrated aluminium oxides and compounds of other elements such as iron. The aluminium compounds in the bauxite may be present as gibbsite 2(Al(OH) 3), böhmite (γ-AlO(OH)) or diaspore (α-AlO(OH)); the different forms of the aluminium component and the impurities dictate the extraction conditions. Aluminum oxides and hydroxides are amphoteric, meaning that they are ...

Read More

May 03, 2018 It is a mixture of hydrous aluminum oxides, aluminum hydroxides, clay minerals, and insoluble materials such as quartz, hematite, magnetite, siderite, and goethite. Bauxite is typically a soft (H:1-3), white to gray to reddish brown material with a pisolitic structure, earthy luster and a low specific gravity (SG: 2.0-2.5). Bayer’s Process is ...

Read More

Fig. 3. World bauxite and aluminium production: X, bauxite; 0, aluminium. a number of rich bauxite deposits. In brief, bauxite is the product of it, situ weathering during which components such as soda, potash, lime, magnesia and some silica were removed in

Read More

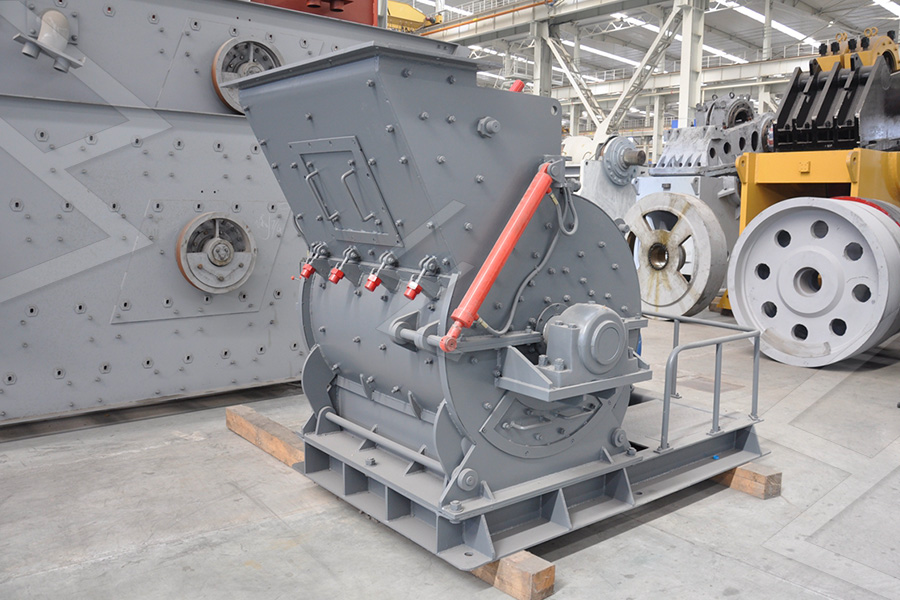

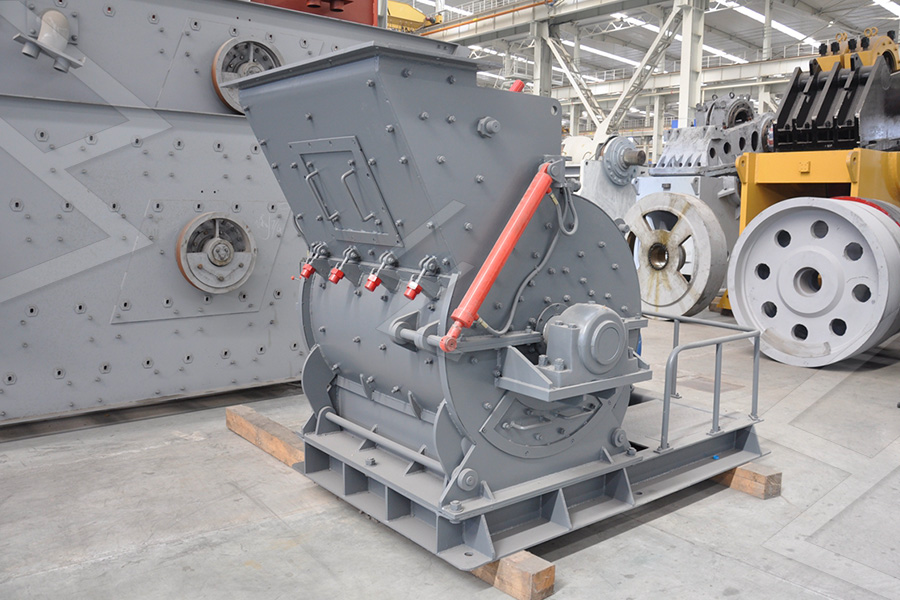

During the extraction of aluminium from bauxite iron oxide as impurity is removed by Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including, During the extraction of aluminium from bauxite iron oxide as impurity is removed by, quarry, aggregate, and different kinds of minerals.

Read More

Feb 24, 2016 extraction ratio of aluminum caused by the change of the phase composition of bauxite after calcination. This is a result of dehydration of low-soluble minerals, which are a part of bauxite, and

Read More

bauxite processing plant equipment for philippines. Philippines bauxite mining sector to benefit from Canada's AlCircle. Processing Plant In The PhilippinesProcessing appliions and equipment for food and beverages. Bauxite Wikipedia. Bauxite, an aluminium ore, is the world's main source of aluminium.

Read MoreCopyright © 2020.Company name All rights reserved.SiteMap