designconstruction and operation of a sag mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including quarry, aggregate, and different kinds of minerals.

Read More

2019-7-10 Cadia SAG mill back in operation - Mining Cadia SAG mill back in operation Following repairs and a period of operational testing, the concentrator 1 semi-autogenous grinding (SAG) mill at Newcrest Mining's Cadia gold operation in New South Wales, Australia, is now operating at full capacity

Read More

SAG Mill Operation at Cortez: Evolution of Liner Design, designconstruction and operation of a sag mill Animination Of Sag Mill Operation 1 YANACOCHA GOLD SINGLE STAGE SAG MILL DESIGN, OPERATION, AND OPTIMIZATION Ben Burger 1. 【Get Price】 Application of Operating Work Indices in Autogenous.

Read More

The results in SAG-Mill line 2 are even more dramatic. Because of segregation on the coarse feed stockpile, SAG-mill 2 receives a higher percentage of coarse material. The KnowledgeScape strategy's ability to maintain smooth and stable operation of the mill was more apparent when contrasted to

Read More

designconstruction and operation of a sag mill Optimizing your SAG mill operationInternational Mining • Efficient operation even at higher mill speeds • Operator-friendly smooth mill operation • Significantly improve wear life • Can be precisely designed to handle the given capacity • Can be easily retro-fitted to existing mills.

Read More

concrete requirement for a sag mill foundation Design construction and operation of the floating roof tank figure maximum allowable sag figure maximum tolerances for outof verticality of the tank shell requirement and determine the minimum the number and size of the anchor bolt for the storage tank it is also important to the civil engineer to design the tank foundation in concrete ring...

Read More

The SAG Mill is a machine added by Ender IO uses Micro Infinity (µI) to grind (or mill) items into their crushed variants like Ores into Dusts.The SAG Mill has four output slots recipes can have 1-4 different outputs with different chances of obtaining those outputs.

Read More

2020-11-3 consumption of the SAG mill. In this paper, the grinding changes of a SAG mill under di erent parameter conditions are explored. Firstly, an experiment on the influence of a single parameter change on the mill’s operation is set up, and then the influence of three parameter changes on the mill’s operation is

Read More

designconstruction and operation of a sag mill. Home designconstruction and operation of a sag mill; MB5X Pendulum Roller Grinding Mill. ... an open circuit operation , SAG mill energy required according to this statement, is 25 times more than the Ab value to produce the same degree of.

Read More

2020-9-28 designconstruction and operation of a sag mill. Videos; Hall of Fame Optimizing your SAG mill operation whereas now the energy efficiency of a plant often rests largely on the SAG mill operation Get Price And Support Online; sag mill operation In the case of the large SAG mill referred to in Fig 1, the mill’s initial volume is 757m 3 when new liners are installed, with the volume on average ...

Read More

The results in SAG-Mill line 2 are even more dramatic. Because of segregation on the coarse feed stockpile, SAG-mill 2 receives a higher percentage of coarse material. The KnowledgeScape strategy's ability to maintain smooth and stable operation of the mill was more apparent when contrasted to the DCS control on the "difficult" line.

Read More

Designconstruction And Operation Of A Sag Mill. Yanacocha Gold Single Stage SAG Mill Design Operation EGL 16 5MW single stage SAG mill to process 5 million tonnes per annum high grade oxide Au Ag ore Operational control feed size distribution grinding media mill liner grate and pulp lifter optimisation have allowed the mill to operate 15 30 ...

Read More

2020-11-3 consumption of the SAG mill. In this paper, the grinding changes of a SAG mill under di erent parameter conditions are explored. Firstly, an experiment on the influence of a single parameter change on the mill’s operation is set up, and then the influence of three parameter changes on the mill’s operation is analyzed.

Read More

SAG mills semiautogenous grinding mills Metso. The range of mill sizes and versatile applications allow SAG milling to be accomplished with fewer lines than conventional setups This in turn contributes to lower capital and maintenance costs for a SAG mill circuit Versatile applications SAG milling extends itself to many applications due to the range of mill sizes available

Read More

designconstruction and operation of a sag mill. designconstruction and operation of a sag mill operation of vertical cement grinding mills For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and .

Read More

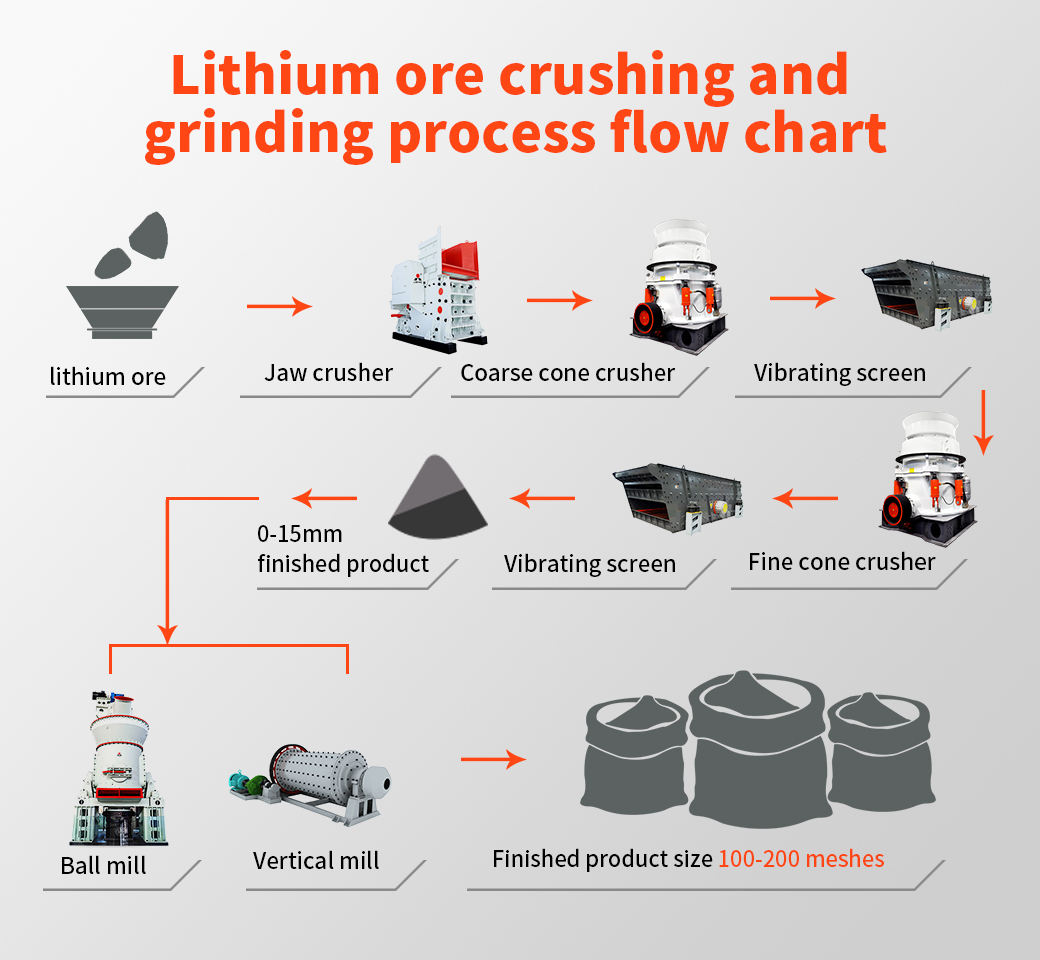

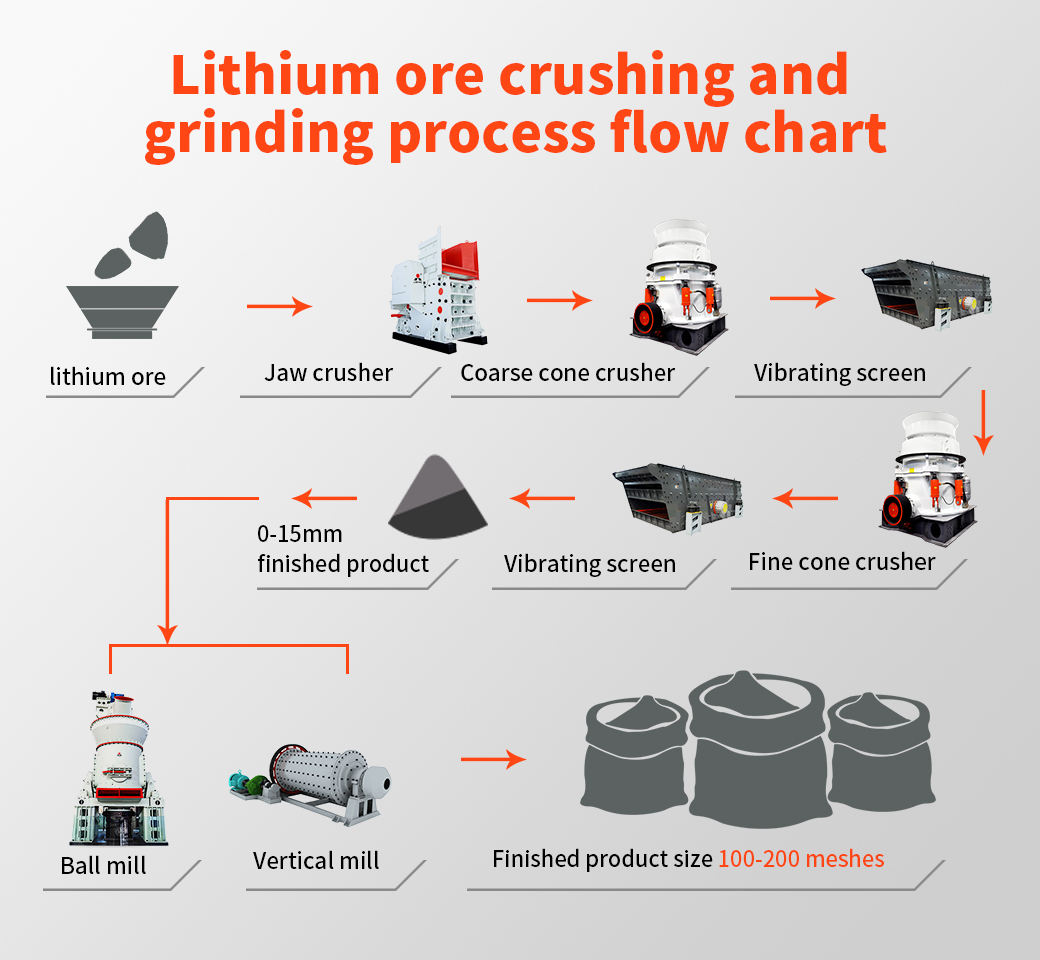

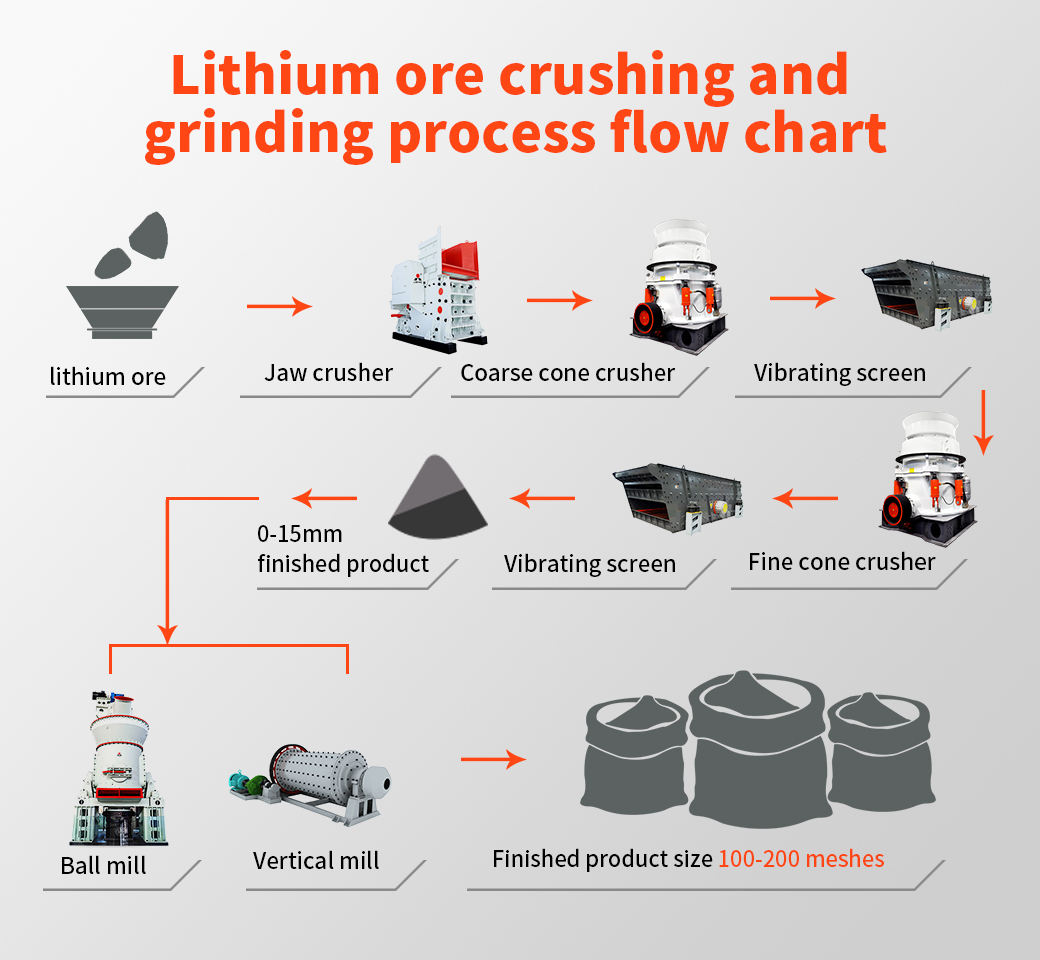

Ball mill is a secondary, and it is used after the SAG mill. 2. SAG mill breaks the raw material into pieces for the further grinding. Ball mill . Optimization of a SAG Mill Energy System: Integrating . 2019-7-1 An optimization is carried out to minimize the yearly cost of energy for the operation of the SAG mill.

Read More

2021-5-24 grinding mill optimization ukraine Construction Waste Crusher Construction waste refers to the construction construction units or individuals to construct lay or demolish all kinds of buildings structures and pipe networks etc and generate the spoil spoil waste residual mud and other wastes generated during the repairing process...As a leading global manufacturer of crushing equipment,

Read More

Foundation design criteria for sag mill and ball mill . Mar 16 2015 sag 2011 paper #144 1. 1 an overview of the design construction commissioning and early years of operation of the sag/ball mill grinding circuit at phu kham copper gold operation in laos.Chat Onlinedesign construction and operation of a sag mill

Read More

2017-9-19 jaw crusher operation of a sag mill pdf anyaresort. Jaw Crusher Working Principle. Jaw Crusher Operation Pdf the handbook pdf of cement plant operation,quarry crusher for,jaw crusher operation of a sag mill pdf,the handbook pdf of cement plant operation,quarry crusher Jaw crusher mainly consists of fram Free Quote. jaw crusher surface and underground sweden .za Copco/Wagner MT 426 .

Read More

designconstruction and operation of a sag mill. Developments in SAG Mill Design and Operation Over the last few years, SAG mill manufacturing technology has advanced rapidly The bounds of mill size have been pushed from two directions Firstly, the advent of ring motors has removed the constraint applied by the power that a.

Read More

Designconstruction And Operation Of A Sag Mill. throughput as does crushing of pebbles from the SAG mill usually minus 60 mm New mill design should always be done at 150 or 152 mm F80 because it is easier to build and operate this way without precrushing Transfer Size T80 Is the 80 passing size of ore as it passes from the SAG mill to the ball mill

Read More

An overview of the design construction commissioning and early years of operation of the sag/ball mill grinding circuit at Phu Kham copper gold operation. Get Price; Development of an AG/SAG mill batch test methodology UQ eSpace. how AG/SAG mill performance varies with mill operating parameters.

Read More

Ball mill is a secondary, and it is used after the SAG mill. 2. SAG mill breaks the raw material into pieces for the further grinding. Ball mill . Optimization of a SAG Mill Energy System: Integrating . 2019-7-1 An optimization is carried out to minimize the yearly cost of energy for the operation of the SAG mill.

Read More

designconstruction and operation of a sag mill. SAG Mill Grinding Circuit Design. but at a higher power efficiency (often assessed by the operating work index OWi, which if used most... Know More. components of the sag mill and ball mill.

Read More

SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill

Read More

2016-6-6 SAG Mill Operation Example. Kidston Gold Mines is a 14 000 tonnes per day rated operation located 280 kilometers west of Townsvilie in Queensland. The principle shareholder is Placer Development Limited. Kidston’s orebody consists of 44.2 million tonnes graded at

Read More

designconstruction and operation of a sag mill. Developments in SAG Mill Design and Operation Over the last few years, SAG mill manufacturing technology has advanced rapidly The bounds of mill size have been pushed from two directions Firstly, the advent of ring motors has removed the constraint applied by the power that a.

Read More

Optimizing Your Sag Mill Operation. Principle of SAG Mill operation SAG is an acronym for semi autogenous grinding SAG mills are autogenous mills that also use grinding balls like a ball mill A SAG mill is usually a primary or first stage grinder SAG mills use a ball charge of 8 to 21 Related items Mortar and pestle Expeller Extruder PAI SAG Mill Training YouTube

Read More

Optimizing your SAG mill operation - International Mining. In the past, when primary, secondary and tertiary crushers fed material directly to large ball mills, the energy efficiency of the concentrator was determined for the most part by the ball mill operation, whereas now the energy efficiency of a plant often rests largely on the SAG mill operation.

Read More

2019-11-26 The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 0.1 mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill

Read MoreCopyright © 2020.Company name All rights reserved.SiteMap