2014-2-5 CEMENT ROTARY KILN Questions Answers Question-1: What is the maximum continuous shell temperature a kiln stands without permanent damage to the shell? Answer-1: The maximum recommended kiln shell temperature varies by plant, by country and by kiln manufacturer, despite the fact that most kiln shells are made of low alloy carbon steel.

Read More

A cement rotary kiln, the world's largest manufacturing machine, is the major component of the cement technological line. The process involves heat and mass transfer between the kiln,

Read More

Rotary Kiln Design Pdf. The rotary kiln type is the typical furnace used in all cement factories. rotary kilns used in the cement industry are much larger in diameter and longer in length than the previously discussed incinerator. view details send enquiry pdf rotary kiln handbook new. Online Chat Cement

Read More

rotary cement kiln using artificial neural networks, 30 (2009) 3468-3473. [5] Bernard Gilbert, Alain Regnault, Fours de cimenterie, four rotatif , BE 8845 Editions techniques de l’ingénieur.

Read More

Residual oil was used as an alternate fuel to natural gas to supply heat in a rotary cement kiln. Principal impurities in the residual oil were Ca, Fe, Mg, Na, Ni, P.S. and V. the kiln operators were concerned about the effects of these oil impurities on observed degradation of the magnesia-based bricks used as a liner in the burning zone of the kiln.

Read More

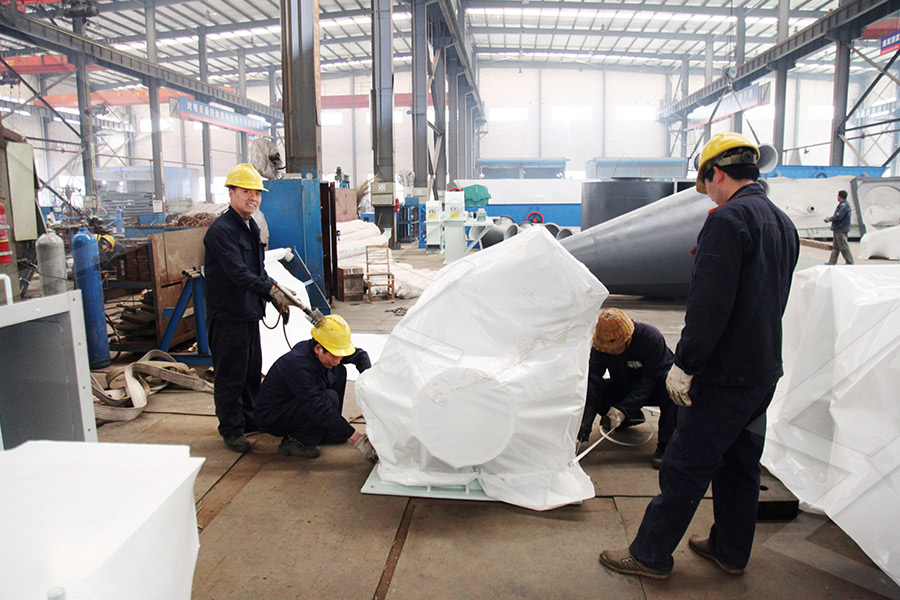

2021-7-9 PDF MECHANICAL COMPORTEMENT OF A CEMENT PLANT ,element analysis of a wet cycle cement rotary kiln 39 2002 17–42 4 K P AZAND M SHARIA T P ANAHI and M POURABDOLI Simulating the mechanical behavior of a rotary cement kiln using ...As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc. we offer advanced,

Read More

cement factory rotary kiln pdf (PDF) Modeling of Rotary Kiln in Cement Industry Cement production is a highly energyintensive process, and the rotary kiln is the most important part of the process Having a comprehensive model of the kiln in order to reduce manufacturing .

Read More

Cement Factory Rotary Kiln Rotating Mechanism - Cement Factory Rotary Kiln Rotating Mechanism. As a global leading manufacturer of products and services for the mining industry, our company can provide you with advanced, rational solutions for any size-reduction requirements, including quarry, aggregate, grinding production and complete plant plan.

Read More

2018-11-15 IS : 8125 - 1976 3. THICKNESS OF SHELL 3.1 The thickness of steel plate for shell different zones kiln shall be as given in Table 2. TABLE 2 THICKNESS OF STEEL PLATE FOR KILN SHELL SL KILNZONE STANDARD THICKNESS OF STEEL PLATE TO BE USED, mm No. r----- h_-_____~

Read More

2020-9-5 The cement plant is one of the most energy-intensive industries, and the rotary kiln consumes significant share of this energy and the amount of consumed fuel has a direct effect on the finished product price (Radwan 2012).The cement plants consume high quantities of power which shape approximately 40% of the total production cost (Chatterjee and Sui 2019; Zanoli et al. 2016b).

Read More

2010-7-14 Cement rotary kiln is the most vital part of a cement factory whose outcome is cement clinker. A rotary kiln is a cylinder with a length of around 70 mete rs and a diameter of around 5 meters in a factory with a capacity of producing about 2000 tons of clinker in a day. The kiln

Read More

CEMENT PROCESSING Hongke Heavy Industry Rotary Kil. The cement clinker calcined After the pletion of preheating and deposition in the preheater the next process is to enter the rotary kiln clinker Further rapid deposition of carbonate in a rotary kiln and a series of reaction with each other as the temperature rises the mineral phase formed by the reaction bees a lot of clinker

Read More

2021-6-3 cement factory rotary kiln pdf Rosendale cement is a natural hydraulic cement that was produced in and around Rosendale, New York, beginning in 1825. From 1818 to 1970 natural cements were produced in over 70 locations in the United States and Canada.

Read More

Cement Factory Rotary Kiln Pdf. Portland cement.Cement is a material with adhesive and cohesive properties which make it capable of bonding minerals fragments into a compact whole.For constructional purposes, the meaning of the term cement is restricted to the bonding materials used with.

Read More

Rotary Kiln Electrostatic Precipitator Design Calculation Pdf. Energy audit calculation for cement mill limestone crusherenergy audit calculation for cement mill limestone crusherCement mill calculation pdf cement process energy saving eccj laos 200610 2 water layout of one japanese cement factory waste tire yard coal yard electrostatic precipitator raw mill crusher sp calciner rotary kiln ...

Read More

DOC PPT TXT PDF XLS IT/ Identification prediction and detection of the process fault in a cement rotary kiln by locally lin IT/ Get Price; LINEAR IDENTIFICATION OF ROTARY WHITE . LINEAR IDENTIFICATION OF ROTARY WHITE CEMENT KILN Golamreza Noshirvani Mansour Shirvani identified for rotary kiln of Saveh white cement factory. Get Price

Read More

cement factory rotary kiln pdf. Rotary kilns for cement plants FLSmidth. The components of success Robust kiln drive station = long lifetime While the ROTAX-2 and 3-base kilns share a number of proven components, the drive station is very different for. Details.

Read More

2019-6-15 rotary kiln operations. Regardless of rotary kiln size or configuration the basic principles outlined in this manual govern the reliable operation of every rotary kiln, calciner, dryer, incinerator, digester and cooler application. For questions or problems with your specific application please contact North American Kiln for assistance.

Read More

2012-4-11 The clinker burning system consists of three parts, i.e. the clinker cooler, the rotary kiln, and the suspension pre-heater (Touil et al., 2005). The function of a clinker cooler in a cement plant is twofold,i.e. to reduce the temperature of the clinker to a level that

Read More

Cement rotary kiln refactory Mining Machinery Co. Pdf heat transfer in rotary kiln from deva cement factory. a cement rotary kiln the worlds largest manufacturing machine is the major component of the cement technological line the process involves heat and mass transfer between the kiln fuel .

Read More

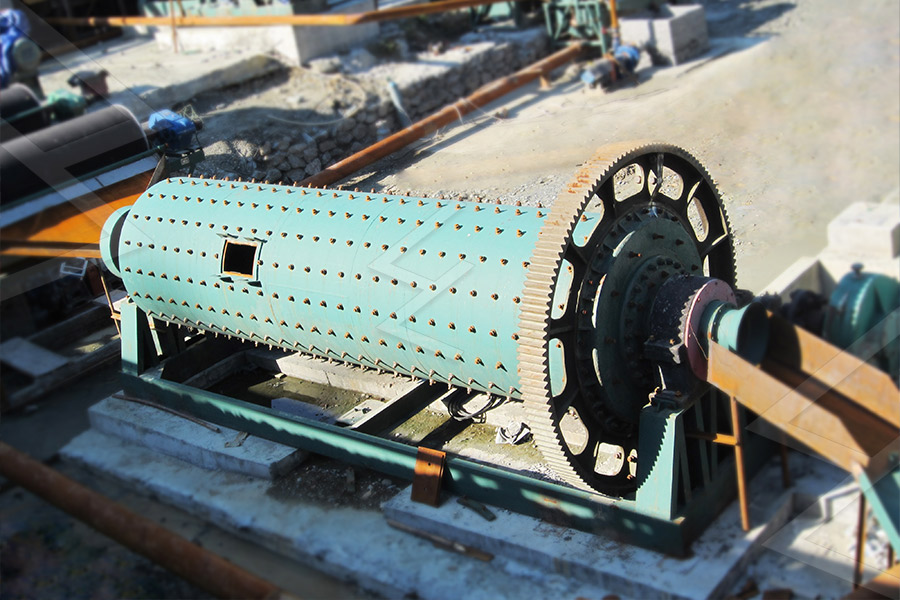

cement factory rotary kiln pdf jjgconstruction.co.za. Rotary kiln (cement kiln) is used for making of cement clinker and there are dry and wet methods to make cement. Rotary kiln (metallurgy chemical) kiln is used for magnetic roasting of iron ore and oxidizing roasting of chrome and nickel in the steel factory.

Read More

2021-6-3 cement factory rotary kiln pdf Rosendale cement is a natural hydraulic cement that was produced in and around Rosendale, New York, beginning in 1825. From 1818 to 1970 natural cements were produced in over 70 locations in the United States and Canada.

Read More

Cement Factory Rotary Kiln Pdf Cement Rotary Kiln CEMENT ROTARY KILN Questions amp; Answers Question-1 What is the maximum continuous shell temperature a kiln stands without permanent damage to the shell Answer-1 The maximum recommended kiln shell temperature varies by plant by country and by kiln manufacturer despite the fact that most kiln ...

Read More

2010-7-14 Cement rotary kiln is the most vital part of a cement factory whose outcome is cement clinker. A rotary kiln is a cylinder with a length of around 70 mete rs and a diameter of around 5 meters in a factory with a capacity of producing about 2000 tons of clinker in a day. The kiln is rotated by a powerful electrical motor.

Read More

2019-5-6 Cement rotary kiln is the most important part of a cement factory whose outcome is cement clinker. A rotary kiln is a cylinder with a length of around 70 meters and a diameter of around 5 meters in a factory with a capacity of producing Masoud Sadeghian is with the Mechatronics Department, School of

Read More

2014-5-15 temperature, and gas components in a cement rotary kiln were obtained by numerical simulation of a 3000 t/d rotary kiln with a four-channel burner. A zone wise heat flux model was presented which accounted for the thermal enthalpy of the clinker formation process and gave more insight to fluid flow, temperature, etc. within the cement rotary kiln.

Read More

cement factory rotary kiln pdf . Cement kiln Wikipedia. Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates.Over a billion tonnes of cement are made per year, ...

Read More

1971-8-17 4. Reaction, of the oxides in the burning zone of the rotary kiln, to form cement clinker at temperatures of approximately 1510°C (2750°F). Rotary kilns are long, cylindrical, slightly inclined furnaces that are lined with refractory to protect the steel shell and retain

Read More

2012-4-11 The clinker burning system consists of three parts, i.e. the clinker cooler, the rotary kiln, and the suspension pre-heater (Touil et al., 2005). The function of a clinker cooler in a cement plant is twofold,i.e. to reduce the temperature of the clinker to a level that

Read MoreCopyright © 2020.Company name All rights reserved.SiteMap