2020-9-9 The coal mill grinding system is an important part of the dry process cement manufacturing. In cement plants, we usually adopt the air swept coal mill system or

Read More

Coal Mill an overview ScienceDirect Topics. With any industrial activity, generation of waste and by-products is expected. In the case of cement manufacturing, the associated process leads to pollution in the following ways: • Dust generation in specific sections of cement plants (crushers, raw mill, coal mill, kiln, clinker cooler, cement mill) •

Read More

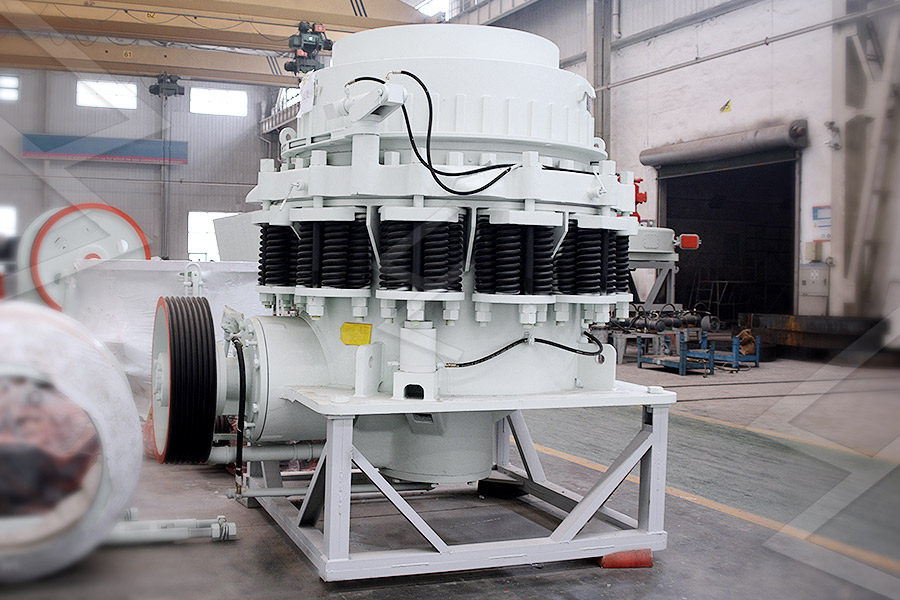

Air-swept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coal.It is the important auxiliary equipment of pulverized coal furnace. The air-swept coal mill runs reliably, can work continuously, also has a large production capacity and less energy consumption.

Read More

2013-1-1 In terms of coal utilisation in the cement manufacturing process, its use as a fuel in rotary kilns is the main area of consideration. 15.3.6. Finish grinding and distribution. After production in the kiln, clinker is stored on site in silos or clinker domes until needed for cement production.

Read More

Here are the five stages of cement production and the steps to maintain consistent raw material quality with minimal chemistry deviation, from quarry to silo to customer. Request information. The Quarry. Crusher and Pre-blending. Raw Mill and Kiln. Coal Mill. Clinker. The first step in the cement process is to extract limestone and clay from ...

Read More

As a trusted cement plant manufacturer of China, AGICO Cement can provide high-quality cement mill and other kinds of cement equipment at competitive prices. Wide product range: For meeting various requirements from different clients, our cement mill range from cement ball mill, vertical cement mill, Raymond mill, coal mill in cement plant, etc.

Read More

Optimize your cement process. Reduce product variation, extend quarry life and meet control requirements. Thermo Fisher Scientific offers a complete line of instruments, equipment and software to help cement producers improve product quality, boost efficiency, lower productions costs, and create safer, cleaner production lines.

Read More

2016-1-25 The mercury mass flows of the coal mill system are presented in Table 3.Similar to that for the raw mill system, the dominant mercury input of the flue gas from the kiln tail contributed 97.0% and 74.1% of the mercury for the coal mill system, much larger than the proportions of mercury input from coal, which were 3% and 25.9% in Plants 1 and 2, respectively.

Read More

Operating data from a coal mill is used to compare the fault detection observer-based method and PCA/PLS models based approach. There are 13 process measurements available representing different temperature, mass flows, pressures, speed etc in the coal mill. The measurement is not updated, if the variation is less than 1%.

Read More

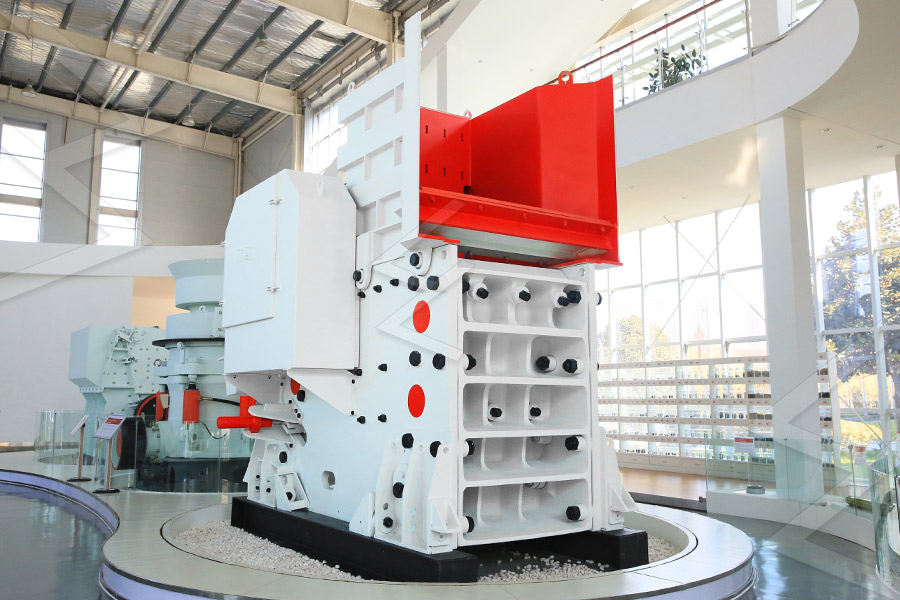

Coal mill_cement production process_lvssn. Coal mill Capacity: 3-55t/h Applicable materials: Cement silicate products new building materials and etc. Application: Cement me tallurgy chemical industry and etc. Coal mill is the main equipment of pulverized coal preparation system which is mainly used for pulverizing coal with various hardness and also for pulverizing coal and ore in cement .

Read More

2021-7-2 Coal Mill In Cement Production Process. coal in the cement industry,plays an important role in the manufacturing process of cement. based on the composition of raw feed a wide range of coal is used. in a cement plant two systems of coal firing are used, namely, a) direct firing and b) indirect firing. in direct firing system, coal is milled on line and is directly fed to the kiln. the.the ...

Read More

coal mill in cement production process As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including quarry, aggregate, and different kinds of minerals.

Read More

The Cement Manufacturing Process. Cement Manufacturing Process The cement manufacturing process starts with the mining of limestone that is excavated from open cast mines Then this limestone is crushed to 80 mm size and is loaded in longitudinal stockpiles Limestone is taken out diagonally from these stockpiles for grinding in raw mill hoppers As mentioned earlier coal is

Read More

coal mill in cement manufacturing. Coal Mill In Cement Manufacturing Process The cement manufacturing process starts from the mining of limestone which is the main raw material for making cement the Coal Crusher is stored in a longitudinal stockpile from where it is reclaimed by a reclaimer and taken to the coal mill hoppers for grinding of fine coal .

Read More

Dry Process Cement Production Line - HAIJIAN. Haijian is capable of offering complete dry process cement production line construction ... During the process of cement production, the majority of raw materials, including lizenithne, clay, iron ore, coal, etc. will be crushed. .... Cement Mill. Get Price

Read More

Coal Mill In Cement Production Process Homepage Of Sbm . Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind ...

Read More

Coal Mill In Cement Manufacturing Process The cement manufacturing process starts from the mining of limestone which is the main raw material for making cement the Coal Crusher is stored. Get Price. Coal Millcement Production Processcement Epcjiangsu.

Read More

Coal Mill in cement production process. A Concrete Cure for Global Warming? - Scientific American- Coal Mill in cement production process ,7 Aug 2008 , A new technique could turn cement from a source of climate changing greenhouse gases into a way to remove , And attaching the Calera process to the nation's more than 600 coal-fired power plants or even steel mills critical review on energy use ...

Read More

Coal mill_cement production process_Cement epc-JiangSu Lvssn. Coal mill is one of the four auxiliary machines in thermal power station and the main equipment of pulverized coal preparation system.It is also suitable for pulverizing coal and ore in cement, metallurgy, chemical industry and other industries.Special steel ball coal mill is a new ...

Read More

2021-7-2 Cement Manufacturing Process Flow Chart. in the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. limestone is the main raw material for cement production, each producing a ton of clinker needs about 1.3 tons of limestone, more than 80% of raw material is limestone.,cement production and quality control a. cement,in line 1 and

Read More

Coal Mill In Cement Making Process. coal mill in cement production process MC World. Coal millcement production processCement epcJiangSu 11행 20191210 Coal mill is one of the four auxiliary machines in thermal power station and the main equipment of pulverized coal preparation is also suitable for pulverizing coal and ore in cement metallurgy chemical industry and other l steel ball coal mill ...

Read More

coal mill in cement production process. The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km. The limestone is excavated from open cast mines after drilling ...

Read More

coal mill in cement production process As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including quarry, aggregate, and different kinds of minerals.

Read More

Coal Mill Process In Cement Plant. Adana Cement Industry Inc operates four separate clinker production lines two coal mills and five cement mills at its Adana plant Expert Optimizer EO which is an ABBs Advanced Process.

Read More

Air-swept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coal.It is the important auxiliary equipment of pulverized coal furnace. The air-swept coal mill runs reliably, can work continuously, also has a large production capacity and less energy consumption.

Read More

Coal Mill In Cement Manufacturing Process. Nov 30, 2017 Coal mill in cement manufacturing process. cement manufacturing process ng and preblending 1crushing in the cement manufacturing process most material must be broken such as limestone iron ore clay and coal etc limestone is the main raw material for cement production each producing a ton of clinker needs about 13 tons of limestone than 80.

Read More

Coal Mill in cement production process. A Concrete Cure for Global Warming? - Scientific American- Coal Mill in cement production process ,7 Aug 2008 , A new technique could turn cement from a source of climate changing greenhouse gases into a way to remove , And attaching the Calera process to the nation's more than 600 coal-fired power plants or even steel mills critical review on energy use ...

Read More

2016-3-1 In July 2014, Sinai Cement Company (SCC) contracted FLSmidth to provide the equipment for it to replace natural gas and mazut with coal for cement production. Similarly, in October 2014, Misr Beni Suef Cement announced plans to build a US$27.9m coal mill by the end of 2015. Next, in November 2014, Titan Cement ordered a Gebr.

Read More

In cement production processes, there are several models for the purpose of studying the use of alternative fuels [4, 36, 39]: phase chemistry , oxidation process of coal tar pitch , cement raw material blending process , reduction of CO 2 , sensitivity analysis of a model used for the design of rotary kiln processes , and a nonlinear model ...

Read MoreCopyright © 2020.Company name All rights reserved.SiteMap