titanium ore processing wet and dry. Wet and dry plants On the right is the wet plant and on the left is the dry plant at the Base Titanium Mine in Ukunda Kwale In the front is the titanium ore Our tour of titanium mining commenced in earnest We were taken to the processing plant There we saw the wet and the dry plant Wet

Read More

Titanium ore processing wet and dry stephwenger. Titanium ore processing wet and dry. Wet and dry plants On the right is the wet plant and on the left is the dry plant at the Base Titanium Mine in Ukunda Kwale In the front is the titanium ore Our tour of titanium mining commenced in earnest We were taken to the processing plant There we saw the wet and the dry plant Wet Plant .

Read More

Titanium Ore Processing Wet And Dry. Vanadium titanium magnetite through once grinding, once coarse crushing, once concentrate, once sweeping of magnetic separation process to sort magnetite concentrates, magnetic tail separate.Copper ore flotation, magnetic separation, gravity separation, or wet smelting,etc.

Read More

Titanium Ore Processing Wet And Dry. Titanium and alloys of titanium powders are enabling to meltless powder metallurgy parts fabrication and feeds for the manyadditive manufacturingprocesses to produce parts. 3 Cost associated with the various processing steps involved in producing titanium by Kroll processing Unalloyed sponge fines powder are nearly 40 of the cost.

Read More

Titanium Ore Processing Wet And Dry. 2018-10-10Titanium Ore Gravity Separation. Introduction of Titanium Ore Gravity Separation Titanium ore gravity separation process is the beneficiation method based on different mineral density to separate mineral.

Read More

Titanium Ore Processing Wet And Dry. Titanium Ore Processing Wet And Dry 2017420sand and ore For drying materials which require long dwell times For easily freeflowing products with fine to medium grain sies Allgaier rotary drum dryers are used particularly in the minerals industry for drying free flowing but also sticky and abrasive wet materials Get Price List Chat Online

Read More

Titanium Ore Processing Wet And Dry. 2017-4-20sand and ore. For drying materials which require long dwell times. For easily free-flowing products with fine to medium grain sies. Allgaier rotary drum dryers are used particularly in the minerals industry for drying free flowing but also sticky and abrasive wet

Read More

titanium ore processing wet and dry; Iron Ore. Our Iron Ore Company of Canada (IOC) is a leading North American producer and exporter of premium iron ore pellets and high-grade concentrate Our operations include a mine with five operational pits a concentrator and a pelletising plant located near Labrador City in the province of Newfoundland ...

Read More

Titanium Ore Processing Wet And Dry. Titanium Ore Processing Wet And Dry. Dongara sand mining to use both dry mining and wet dredging mining techniques the dongara titanium minerals project will be developed using a combination of dry mining methods as well as wet dredging the ore bodies will be accessed following the dewatering of the superficial aquifer and the water required for processing ...

Read More

2016-5-9 The value of titanium in sponge form is presently worth $9 to $10 a pound; in plate and sheet is 2 to 3X that. Titanium Ore Extracting Flowsheet. The flowsheet shown was developed for a mixed rutile and ilmenite ore

Read More

Titanium Ore Processing Wet And Dry. Titanium Ore Processing Wet And Dry. Dongara sand mining to use both dry mining and wet dredging mining techniques the dongara titanium minerals project will be developed using a combination of dry mining methods as well as wet dredging the ore bodies will be accessed following the dewatering of the superficial aquifer and the water required for processing ...

Read More

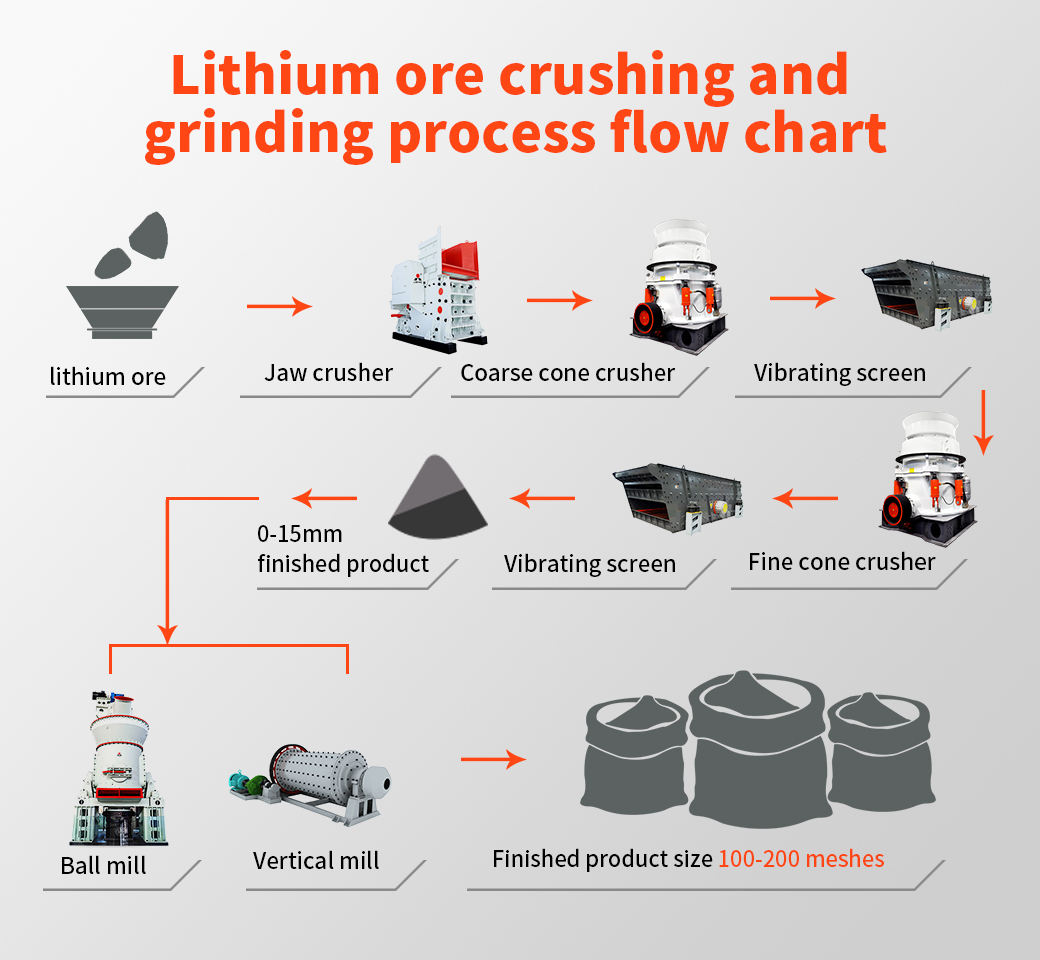

Crushing and Grinding Wet Sticky Ore. Metallurgical ContentSolution to the Wet Ore Processing ProblemThe Wet Ore Processing FlowsheetCRUSHING AND SCRUBBINGCLASSIFICATION AND THICKENING OF PRIMARY SLIMESLARGE TONNAGE CRUSHING PLANTSGRINDING AND CLASSIFICATION FLOTATION In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy

Read More

Titanium Ore Processing Wet And Dry. Titanium Ore Processing Plant, Titanium Ore Processing. Alibaba offers 37 titanium ore processing plant products. About 72 of these are mineral separator, 16 are other mining machines. A wide variety of titanium ore processing plant options are available to you, such as gravity separator, sprial separator ...

Read More

2016-5-9 The value of titanium in sponge form is presently worth $9 to $10 a pound; in plate and sheet is 2 to 3X that. Titanium Ore Extracting Flowsheet. The flowsheet shown was developed for a mixed rutile and ilmenite ore containing some magnetite. Concentration in

Read More

Alibaba features a broad selection of optimal quality titanium ore processing that work with high precision and make your work easier. Grab these titanium ore processing at low prices.

Read More

titanium ore processing offers 242 titanium ore processing plant products. About 86 of these are Mineral Separator, 0 are Cement Making Machinery, and 1 are Other Mining Machines. A wide variety of titanium ore processing plant options are available to you, such as local service location, key

Read More

Dry Processing V S Wet Processing Of Iron Ore. titanium ore processing wet and dry Beneficiation of Iron Ore and the treatment of magnetic iron taconites stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation

Read More

2009-8-26 the first dry processing stage, followed by magnetic fractionation using a combination of RED and RER separators to produce the various grades of titanium-mineral products. Typical chromite process flowsheet In some cases, chromite concentrates can be produced

Read More

ILMENITE (Iron Titanium Oxide) - Amethyst Galleries. It is these layers that constitute a rich ore body for titanium miners. ... Placer deposits often contain both rutile and ilmenite and there are enough of these ... therefore ilmenite is a minor ore of iron as the magnetite and ilmenite are processed for...

Read More

2021-9-17 Titanium Ore is a Hardmode ore which can possibly replace Adamantite in a given world and is functionally the same. Titanium, like all Hardmode ores, is generated upon destruction of an Altar with a Pwnhammer or higher. Like Adamantite, a Mythril Drill / Orichalcum Drill (or their pickaxe equivalents) with 150% Pickaxe power or better is ...

Read More

2021-6-2 Titanium Ore Processing Wet And Dry. Possibilities For All Flotation Treatment of Titanium Ore Generally on complex titanium ores it is advisable to use the combination flowsheet shown An ore of magnetite and ilmenite may however employ wet magnetic separation to remove magnetite and all flotation for recovery of the ilmenite in a high grade ...

Read More

Crushing and Grinding Wet Sticky Ore. Metallurgical ContentSolution to the Wet Ore Processing ProblemThe Wet Ore Processing FlowsheetCRUSHING AND SCRUBBINGCLASSIFICATION AND THICKENING OF PRIMARY SLIMESLARGE TONNAGE CRUSHING PLANTSGRINDING AND CLASSIFICATION FLOTATION In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy

Read More

Tbk. Currently tin ore processing system in KIP produces high grade tin ore ±70% Sn . By applying Processing Plant PPBT with a larger amount so that it will add the cost of transportation and processing costs in PPBT. A and B at wet processing. To get to the dry processing concentrate will be dried before using the.

Read More

manganese ore magnetic separator 1. magnetic separator introduction: The iron ore dry magnetic separator is a piece of mineral processing equipment used to recover ferromagnetic materials. It is fit for processing fine, feebly magnetic materials, such as magnetite, pyrrhotite, ilmenite and other materials.

Read More

2021-9-18 Dry processing at Vale. In the last 10 years, Vale invested almost R$66 billion in facilities and development of technologies for the dry iron ore processing production. Today, most of our iron ore production (about 60%) is through dry processing. The natural moisture processing is used at Carajás and Serra Leste mines, at S11D Eliezer Batista ...

Read More

2015-9-10 Wet grinding Neg Neg Dry grinding with air conveying and/or air classification (SCC 3-03-024-09)e 28.8 C 26 C Dry grinding without air conveying and/or air classification (SCC 3-03-024-10)e 2.4 D 0.31 D Drying--all minerals except titanium/zirconium sands (SCC 3-03-024-11)f 19.7 C 12 C Drying--titanium/zirconium with cyclones (SCC 3-03-024-11)f ...

Read More

2015-2-10 Many iron ore producers are facing challenging times; processing crude material with rising levels of impurities and a volatile iron ore price. Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore to earn more per shipped tonne. High-end steel production at a low coke consumption level and a high productivity rate can only be achieved by using high-quality ...

Read More

2019-8-23 The wet process includes three stages of ore preparation, ore beneficiation processing and product processing. The beneficiation stage may include hydraulic grading, flotation, selective flocculation, magnetic separation, chemical treatment (bleaching), etc. to

Read More

minerals Article Characterization and Pre-Concentration of Low-Grade Vanadium-Titanium Magnetite Ore Chengbao Xu 1, Yimin Zhang 1,2,3,4,*, Tao Liu 1,2,4 and Jing Huang 1,2,4 1 College of Resource ...

Read More

Screening is an important operation in dry and wet closed circuit mineral processing applications. Most of the operations have seen the benefits of using fine wet screens in primary grinding ...

Read MoreCopyright © 2020.Company name All rights reserved.SiteMap